Dental Quality Assurance Using Plan, Do, Study, Act (PDSA): Part 1

By Robert Winter on December 1, 2022 |

Improving the level of care provided to your patients is at the forefront of most dental professionals. Taking continuing education courses and collaborating with peers is one way that you learn new techniques and enhance your skills. Incorporating the scientific principles used in other healthcare settings to advance the quality of clinical care you provide will also improve patient outcomes. There are many dental quality assurance activities that can be applied to your clinical processes which can ultimately improve the patient experience and add more value to your practice.

The process of dental quality assurance has originated in the manufacturing world, where efficiency and reducing costly errors are key to successfully competing in local, regional, and global markets. The techniques have been adapted to meet the needs of complex systems where multiple systems or teams were present as part of the overall process. No matter what type of outcome you seek to improve, one question always needs to be answered; how will you know when you have reached your desired goal or objective?

A system that I have used for years in my clinical practice and in our dental laboratory is the Plan, Do, Study, Act (PDSA) model (Figure 1). It is adaptable to any quality issue you may want to address and is very simple to implement. It provides you with a structure to figure out what is behind the problem, is interactive (you can pull in your colleagues or assistant to help you brainstorm) and is inclusive in nature. It uses quantitative measures to define your goals, outcomes, or quality improvement parameters. The first part, and the most important, as it sets up your entire process, is the planning stage.

Dental Quality Assurance Plan, Do, Study, Act (PDSA) Model

Step 1: Plan

Define the Problem

Do not assume you know why you are not able to reach your clinical goal. You need to determine where the problem exists by doing an unbiased and comprehensive analysis. Get input from as many people as you can. Consult colleagues, trusted mentors, and members of your dental/interdisciplinary teams to help you brainstorm. You will want to start this process with a clear end goal in mind.

Let's start with this an example. Assume you have a problem bonding only veneer indirect restorations (crowns or other partial coverage restorations are not a problem). It is important to clearly identify when or where the problem occurs and any contributing factors. You also need to identify all the stakeholders (who is all involved or affected by the problem), and how they may contribute to the issue being addressed.

Why is there only a problem when bonding veneer restorations? Is it only when using a specific type of dental restoration material or is it with all types of materials you use? Is it that you do not know the correct bonding protocol for the type of restoration being inserted or type of bonding system used? Is it a patient issue or a clinician issue?

It is important to drill down to and include as many specific underlying details and causes of the problem as possible.

Identify the Desired Outcome

It is not enough to just say you want all the restorations to bond appropriately at the insertion appointment. You need to know what you want to accomplish and the timeline for accomplishing it. The outcomes should be measurable and specific. For example: All veneer restorations I insert will bond according to expectations by December 31.

Determine the Steps Needed to Reach Your Outcome

Then determine what steps you need to reach your desired goal or outcome.

- List and analyze all the steps in the current process (a cause-and-effect diagram is great for this)

- Identify all the stakeholders – who is involved in the process? It is important that whoever is involved in solving the problem is involved in the problem identification and outcome planning process

- Determine what data/information you need to collect

- Decide how you will collect and analyze the data

- What is the current baseline (20% bond without difficulty? 50%? None?)

- Establish what steps you need to take and the timeline for the change.

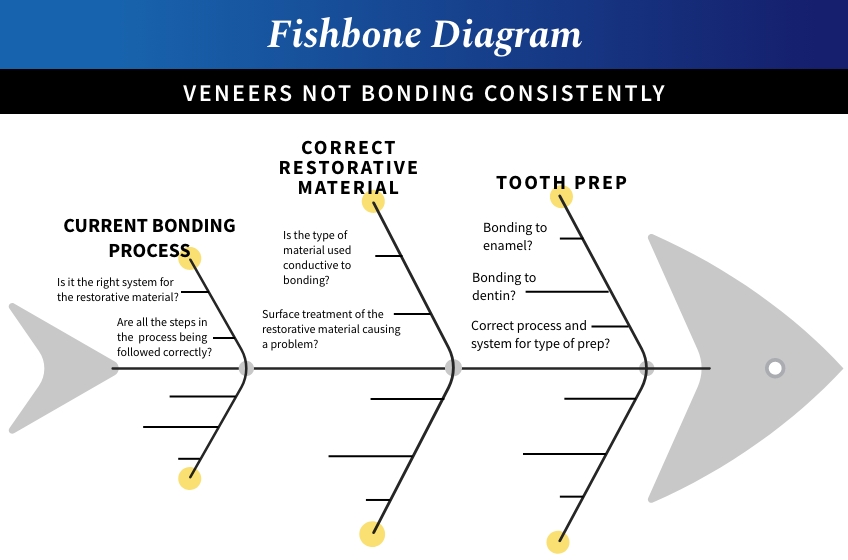

Cause and Effect Diagram

To help you clearly define the problem, you need to determine the causes and effects of your current system of bonding the restorations to get to the root-cause of the problem. My personal favorite root-case analysis tool is the fishbone diagram (Figure 2). It's called that because a completed diagram can look like the skeleton of a fish. You can draw it out on a piece of paper or whiteboard with input from your colleagues, office staff, or dental technician/lab, or use an online template for the process.

If doing it without a template:

- Write the problem in a box on one end of the paper or whiteboard (veneers restorations not bonding consistently)

- Draw a line horizontally from the box (this looks like the head and spine of a fish)

- Draw lines off the spine for each factor that is contributing to the problem, and label it.

- This can be people involved with the problem, systems, equipment, materials, external forces, etc. In the example I provided I only listed three – bonding process, restorative material, and tooth prep. There are others I am sure you can think of.

- Try to draw out as many factors contributing to the problem as possible.

- For every factor you listed, write out all the possible causes you can think of for why you are unable to consistently bond veneer restorations. I listed two or three on the example, but you may have more depending on how deep a dive you do.

- Now sit back and analyze what you have documented. Depending on the complexity of the issue/problem, you can now dig even further. You may need to contact outside vendors, your lab, patients, etc. Sometimes doing a survey with your peers to see what works in their practice is helpful.

Establish a Plan

Once you have identified the potential causes of the problem, the next step is to develop a plan to improve the process.

For example, if the bonding system you are using is appropriate for the restorative material being used, try to identify what steps in the process from preparation to the restorations return from the laboratory for potential steps that may be the root of the problem. Once that is done, it is important to determine exactly what you will do, who will do it, and the target completion date. Just like when you went through the process to determine the cause of the problem, the plan should be detailed and specific.

An example of a detailed action plan is shown in Figure 3. Making a similar chart and posting it where everyone who is involved in the process can see it, helps to keep everyone accountable for finding the solution.

Hopefully you find this helpful when trying to determine why you are not meeting your clinical goals and help you to improve the quality of the care you provide to your patients. Remember, do not assume you know what the cause of the problem is. I find when people reach out to discuss a clinical problem, the underlying reason is often not what the person thinks it is. In the final part of this article, I will discuss the Do, Study, and Act portion of the PDSA quality assurance process.

Robert Winter, D.D.S., is a member of Spear Resident Faculty.

SPEAR PRACTICE SOLUTIONS

Make Your Practice Vision a Reality

Discover how the customizable Spear Practice Solutions business framework is built to address your unique practice challenges. You’ll get dedicated coaching and consultation, targeted learning from Spear faculty, real-time analytics and customized action plans to help your team meet its goals.

LEARN MORE