Is Flexural Strength a Keystone Property of Restorative Dental Materials?

By Doug Benting on January 26, 2023 | commentsAdvancements in restorative dental materials that improve oral health, appearance, and chewing function have added a level of energy and excitement in dentistry. And while goals in developing restorative materials include a focus on how light interacts with a restoration as well as providing durability & wear resistance, the characteristics of restorative dental materials are noticeably different than material properties measured for natural teeth. The question becomes: why is it that measurements related to bone, dentin, enamel do not even approach the flexural strength values reported for lithium disilicate or zirconia?

The magic of a natural tooth includes its interaction with the surrounding structures, including the periodontal ligament. Comparing flexural strength values of specific dental materials provides useful information, but what other information might be important to consider — particularly when evaluating flexible materials? If the goal is to create material that mimics human tissue, flexural strength may not be as important at the evaluation phase.

The Keystone Material (Species) Concept

Paine's work from the 1960's focused on starfish, both along the coast of Washington State, as well as those found along the Great Barrier Reef. The specific starfish evaluated as predators were determined to have a much greater impact on the diversity of the environment than would be expected simply by counting their numbers. The original idea was to demonstrate that a specific species within an ecosystem played an outsized role in maintaining the stability and the diversity of the immediate community (See References).

When thinking about material properties of specific restorative dental materials, would flexural strength fit within the idea of a “keystone concept?” Bending strength makes sense with a typical stress/strain curve to demonstrate the point of failure or fracture. What is the difference in the information gained when comparing a 3-point bending test and a 4-point bending test? How is flexural strength reported by the manufacturer of the specific dental material? How much is left unknown or assumed with the flexural strength values reported?

Flexural Strength of High-Performance Polymers

High-performance polymers such as Bio-HPP and Pekkton (represented by PEEK and PEKK, respectively, in dental uses) are used for specific scenarios including healing abutments, provisional abutments, dental-implant-supported frameworks, and removable partial denture frames.

The material properties are typically presented as being comparable to human tissues such as bone and dentin (Figure 1). Working with restorative dental materials intended to have a little 'give' or the ability to flex like natural structures requires an understanding of how the dimensions of the material influence the mechanical properties. The length of the material as well as the height represent two 'keystone' features influencing the mechanical properties of a high-performance polymer.

The point of focus in the formula presented in Figure 2 is the outsized influence of length and height. To make the math easier, let's work with equal values for both length and height of 3mm – each with a cube root attached, meaning 3 X 3 X 3 = 9. For example, if a polymer were to increase the length of the cantilever from 3mm to 10mm (10 X 10 X 10 = 1000) to include a first molar, the force (F max) required to bend the material is reduced. Vertical height is typically limited by restorative space available-in this example the polymer was re-designed for an increase in height from 3mm to 5mm (5 X 5 X 5 = 125). The formula emphasizes any changes in height by quadrupling the value (4 X 125 = 500) where 2mm of height increase represents one-half of the influence of 7mm of length increase.

Manufacturers of dental materials have committed to a specific value for flexural strength to assist in comparison. Examples for flexural strength comparing several materials are:

- Pekkton (Polymer) 200 MPa

- Titanium 600 MPa

- Milled PMMA 110 MPa

- Zirconia (3Y-TZP) 1,200 MPa

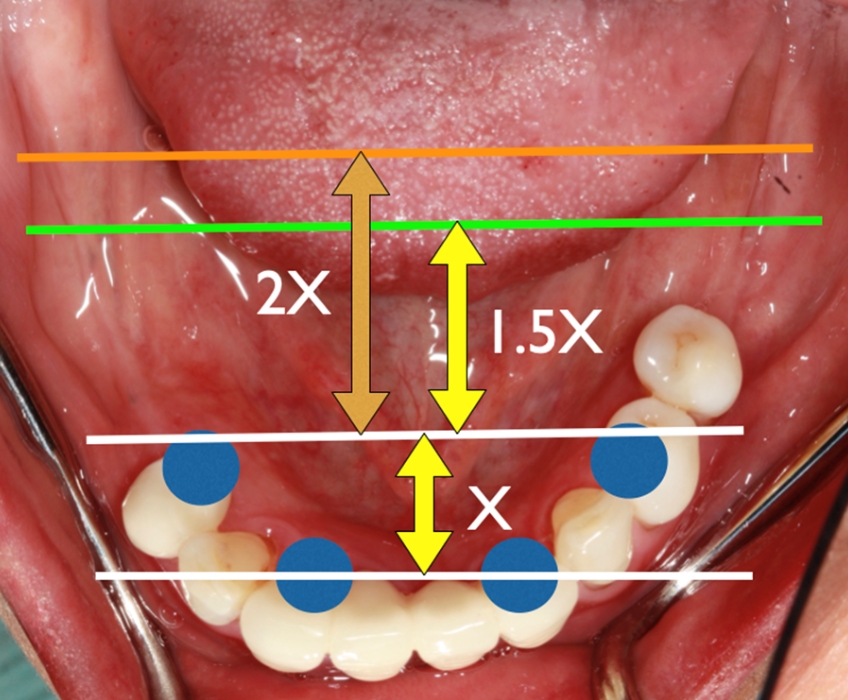

Technically, a dental-implant-supported fixed hybrid prosthesis could be made with any of the four restorative dental materials. Based on the position of the dental implants within the maxilla and/or mandible and the anticipated position of the teeth it is reasonable to assume that there could be variability in design as well as a large variation between materials in terms of flexural strength. The distance between the anterior and posterior implants measured as the “AP spread” could influence the length of the substructure extending distally (Figure 3).

Pekkton is an example of a high-performance polymer designed with a compressive strength like cortical bone and dentinal tooth structure. It comes in a package with a stated flexural strength of two hundred MPa. Working with the example of a dental-implant-supported hybrid prosthesis, extending a cantilever distally will at some point decrease the flexural strength based on the arithmetic demonstrated in Figure 2. Refining the design of the Pekkton framework with a focus to increase the vertical height will have a considerable influence on increasing the stiffness of the material. The added stiffness becomes valuable when extending distally to increase the cantilever length of the framework. There is a limit to the cantilevered extension of the high-performance polymer framework whether for use with a dental implant supported restoration, or for a removable partial denture (Figure 4).

The Impact of Heat on Restorative Dental Materials

The question remains, if flexural strength is the ultimate the goal of a dental material, how much greater than the flexural strength of alveolar bone and dentinal tooth structure is adequate? Is there an example of a dental material where flexural strength is a factor of decreased importance? A recently published article (Gad, et. al. 2022, see reference) emphasizes the factors of the oral environment with an influence on the durability of restorative dental materials. Specifically, in the introduction, it is noted that temperature changes occur 20 to 50 times per day at a range of 5 to 55 degrees Celsius (41 to 131 degrees Fahrenheit).

One additional advantage of zirconia, for example, is a low specific heat. Changes in temperature have practically no influence on the material properties. Conversely, temperature could have a noticeable impact on high-performance polymers, the materials designed and engineered to have a comparable flexural strength to what has been measured for human tissues. Dentsply-Sirona, for instance, has focused on the material property “work of fracture,” which incorporates body temperature into the measurement of material properties (BAM technology) that is showing promise as an important consideration for improved durability with printed denture base polymers.

Even though all dentists have the same goals in caring for their patients. The techniques and materials available continue to advance the level to which these goals can be met. It will be interesting to see the progress in restorative dental materials in the coming years as technology advances.

Douglas G. Benting, D.D.S., M.S., F.A.C.P. is a member of Spear Resident Faculty.

References

- Cottee-Jones, H. E. W., & Whittaker, R. J. (2012). Perspective: the keystone species concept: a critical appraisal. Frontiers of Biogeography, 4(3).

- Gad, M. M., Fouda, S. M., Abualsaud, R., Alshahrani, F. A., Al‐Thobity, A. M., Khan, S. Q., ... & Al‐Harbi, F. A. (2022). Strength and surface properties of a 3D‐printed denture base polymer. Journal of Prosthodontics, 31(5), 412-418.