The Use of a Plaster Verification Jig to Ensure Accuracy of the Master Cast Jig

Verification jigs are prosthetic devices used to confirm the exact position of implant analogs on the master cast, ensuring a passive fit of the final prosthesis. They can be fabricated from materials such as polymethyl methacrylate, resin, or plaster, and constructed either on the master cast or intraorally.

Plaster, in particular, offers several advantages: it is inexpensive, quick, and easy to use. Its greatest benefit, however, lies in its brittleness — if the jig does not align accurately when fastened to the implants intraorally, it will fracture, revealing any discrepancies.

The following step-by-step technique demonstrates fabricating and testing a plaster verification jig. This approach provides a fast, cost-effective, and reliable method to confirm the accuracy of the master cast, and it is strongly recommended before fabricating any full arch prosthesis.

Master cast of four tissue-level analogs with soft tissue moulage.

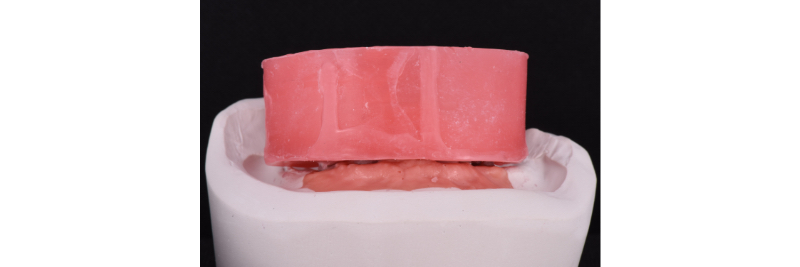

A wax matrix is used to hold the plaster while setting. The plaster is then poured over the temporary cylinders.

Front view of the wax matrix on the master cast.

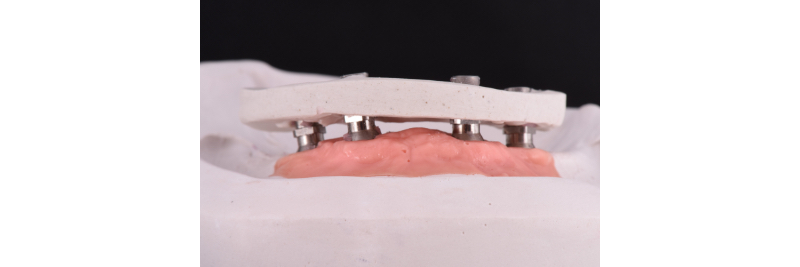

Front view of the plaster verification jig on the master cast.

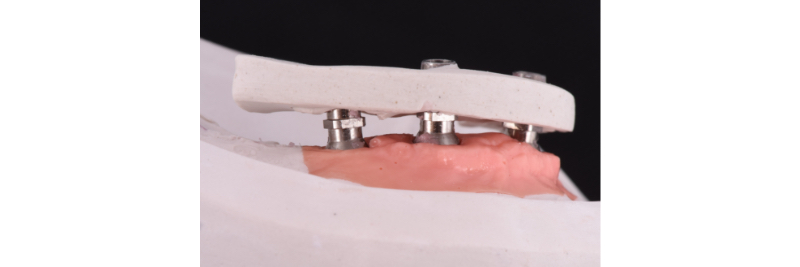

Lateral view of the plaster verification jig. Note that the thickness of the material is kept to a minimum.

Plaster a jig on a mirror. Note the distance between the temporary cylinder’s platform and the jig, allowing space for the soft tissue.

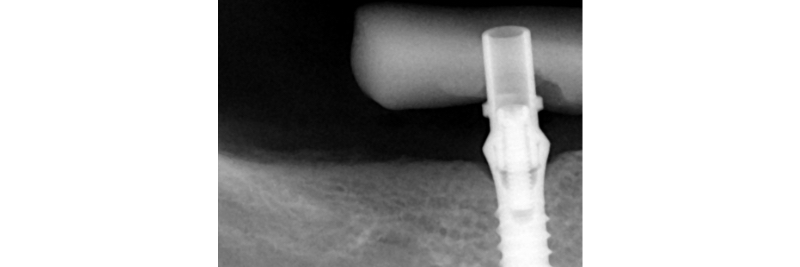

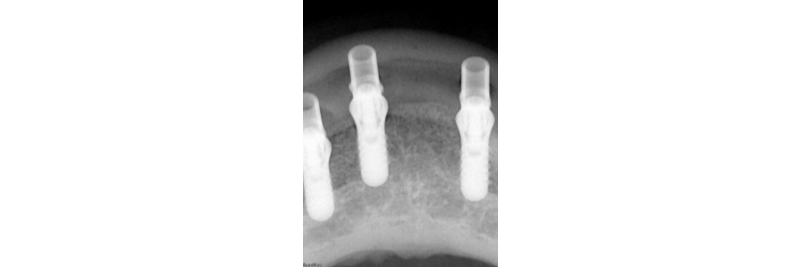

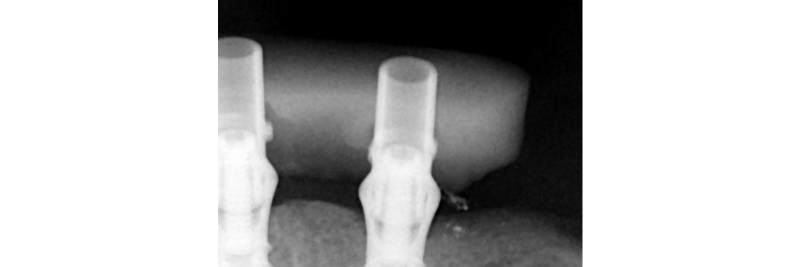

Jig fastened to the implants. One screw test is performed to confirm passivity.

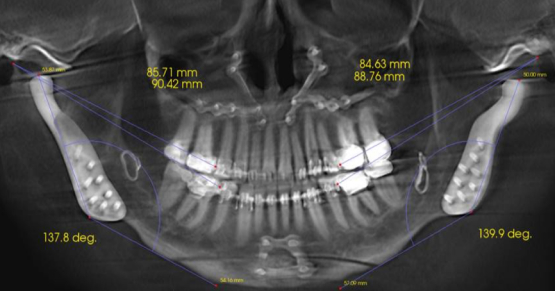

Radiographic verification of the temporary cylinder fully seated on the implant platform.

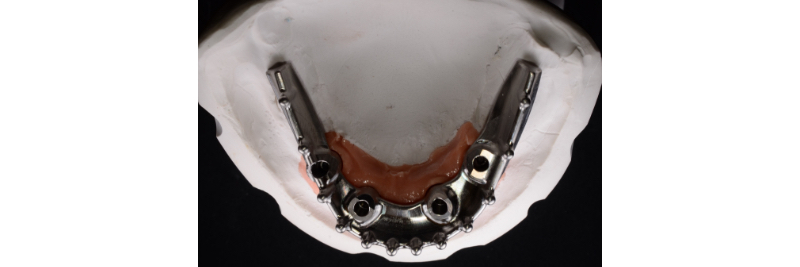

CARES milled titanium bar on the verified master cast.

Front view of the milled titanium bar on the master cast.

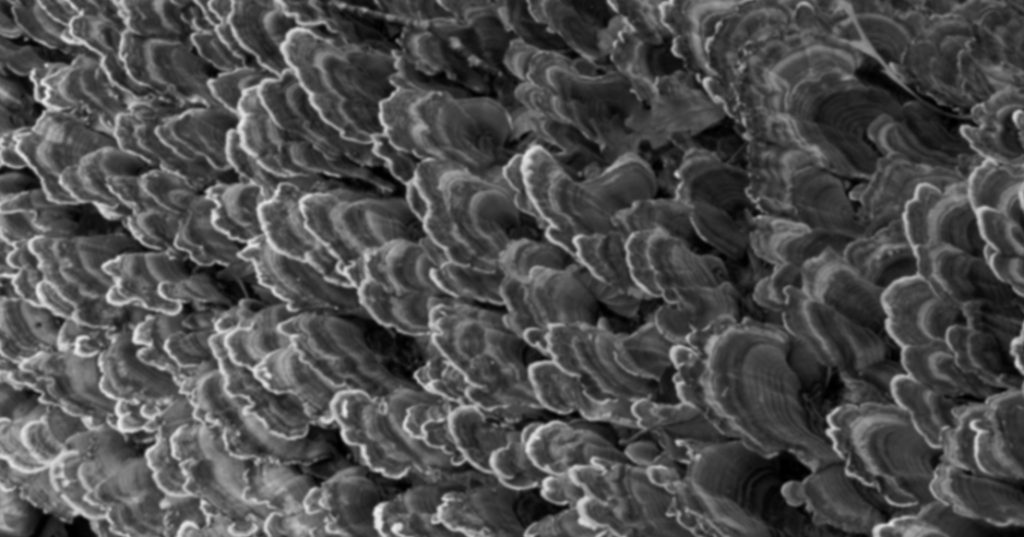

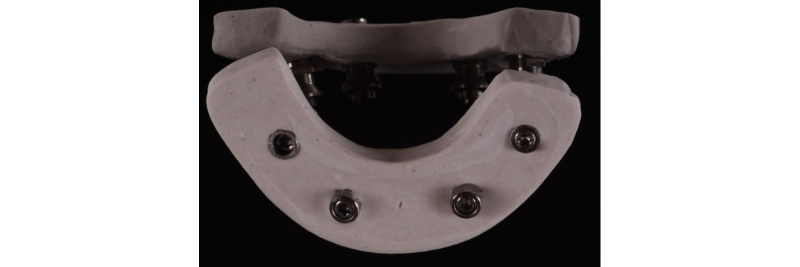

Intaglio surface of the milled titanium bar.

Front view of processed and polished implant hybrid prosthesis on the master cast.

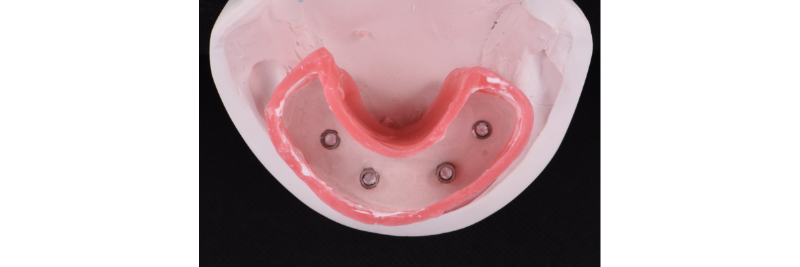

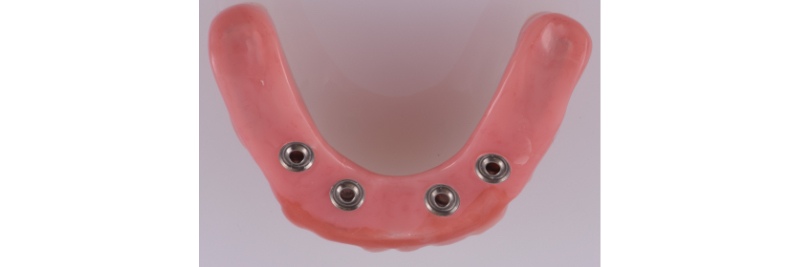

Intaglio surface of the processed and polished implant hybrid prosthesis.

Front view of the implant hybrid prosthesis intraorally.

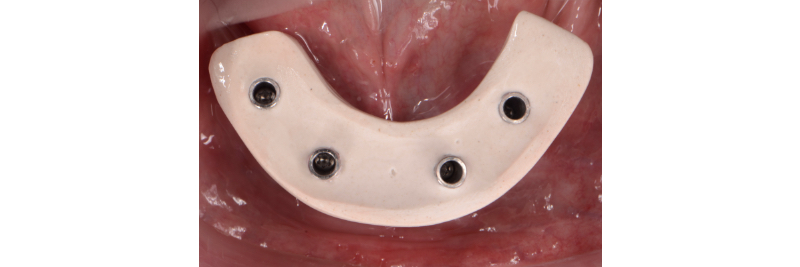

Occlusal view of the implant hybrid prosthesis intraorally.

SPEAR campus

Hands-On Learning in Spear Workshops

With enhanced safety and sterilization measures in place, the Spear Campus is now reopened for hands-on clinical CE workshops. As you consider a trip to Scottsdale, please visit our campus page for more details, including information on instructors, CE curricula and dates that will work for your schedule.

By: Ricardo Mitrani

Date: August 12, 2019

Featured Digest articles

Insights and advice from Spear Faculty and industry experts