Screw-Retained Restorations With Off-Angle Implants

With a better understanding of the interaction of excess cement, peri-implant mucositis, and implantitis, the trend for implant restorations is moving back to screw-retained crowns rather than using luting cements.

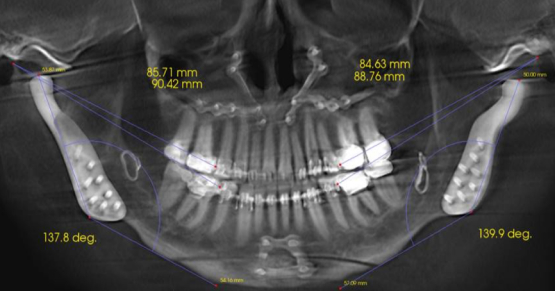

Implant placement and the position of the implant platform relative to the final restoration are critical factors in whether the restoration can be screw-retained or cemented.

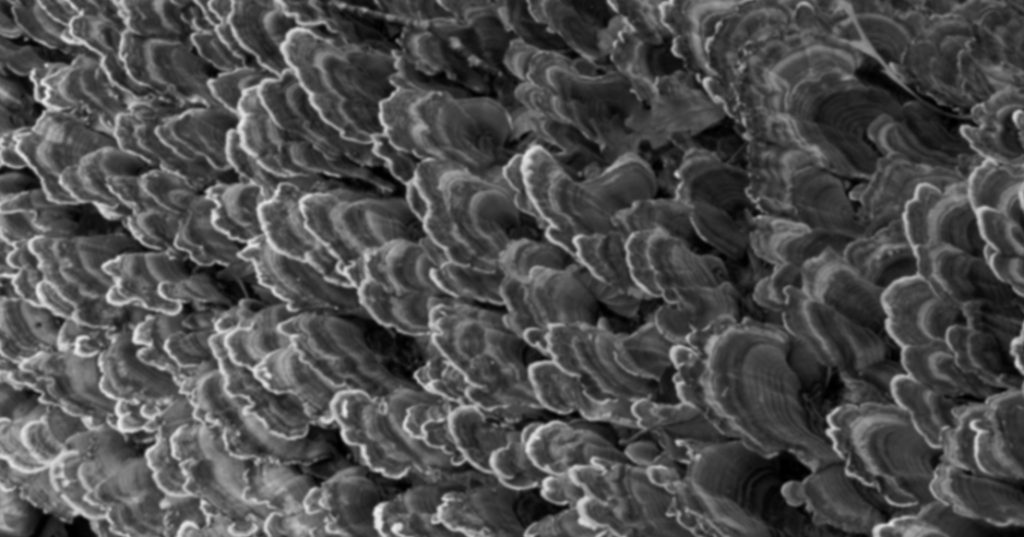

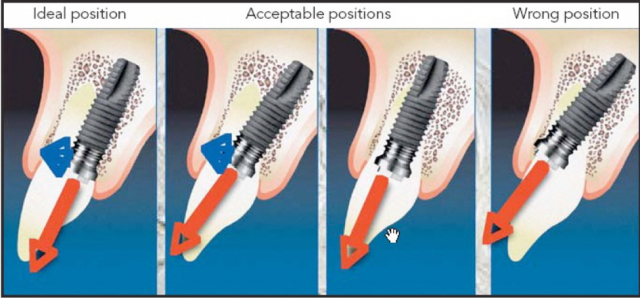

In order to have a screw-retained restoration that is esthetic, the implant must be placed in a position so that the screw access opening is on the palatal surface of the restoration and preferably can exit through the cingulum. With standard abutment choices (even if they are custom abutments) there must be straight-line access to the screw channel.

Implant companies have reacted and created angled abutments that can compensate for less-than-favorable implant positions. Even with this angulation, the restoration requires that it be cemented, making the ability to create a custom abutment difficult or impossible.

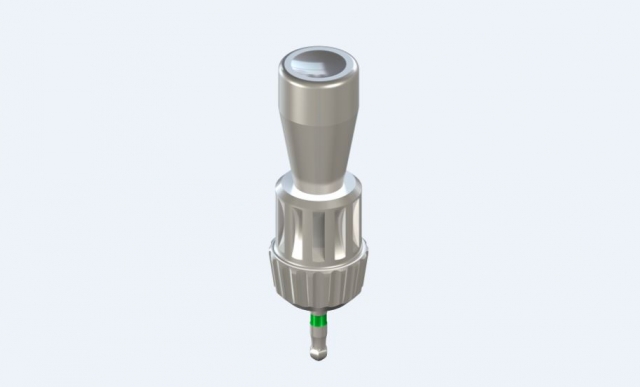

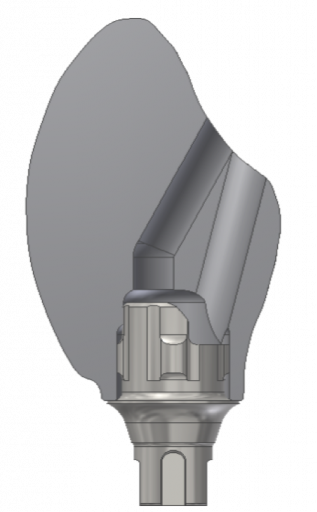

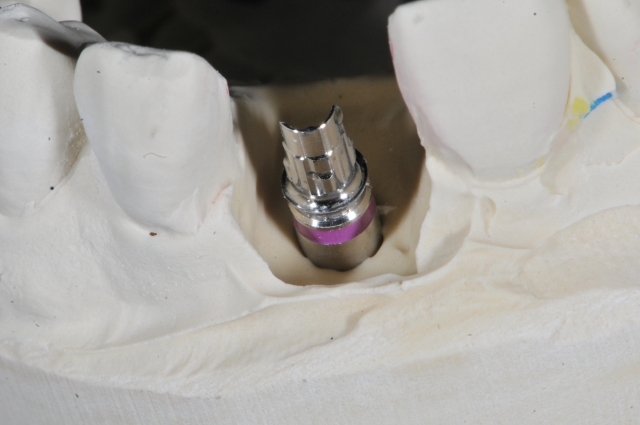

Manufacturers have also responded to this dilemma. Straumann, for example, has created an angled titanium base abutment called the angled variobase (StraumannTM VariobaseTM for Crown AS). It allows for a custom abutment to be fabricated and compensates for the implant’s off-angulation by allowing access to a unique screw head with a special multiangle driver.

The cutaway on the palatal or lingual surface of the abutment allows greater angulation for screw access.

The head of the screw is not a traditional hex, nor is the head of the driver, allowing the screw to be torqued with a divergent path. The system is designed to be used together.

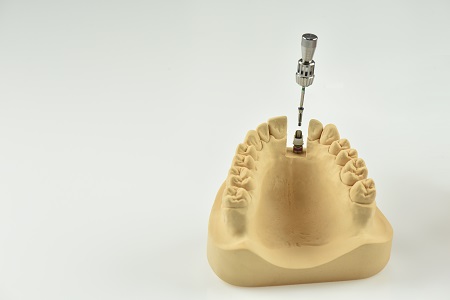

The process is straight forward: you make an implant level impression, send it to your lab and they wax the custom abutment/final restoration using a “burnout” coping specific to the angled variobase. The wax-up is scanned, then milled and cemented to the variobase.

The angled screw channel allows the driver access through the cingulum or occlusal surface and eliminates the need for a cement-retained restoration. The shape of the driver head and the head of the screw allow for the driver to solidly engage, even without straight-line access, to torque the screw to 35 ncm.

In the case below, the anterior portion of the implant platform is too far labial. The angled variobase was used to create a final result that compensates for the implant position and is esthetic.

Thanks to Unice Dental Lab for the clinical photographs.

SPEAR STUDY CLUB

Join a Club and Unite with

Like-Minded Peers

In virtual meetings or in-person, Study Club encourages collaboration on exclusive, real-world cases supported by curriculum from the industry leader in dental CE. Find the club closest to you today!

By: Steve Ratcliff

Date: November 7, 2018

Featured Digest articles

Insights and advice from Spear Faculty and industry experts