Where Is the Line With Locators?

If you’re working with locator abutments and attachments and everything is running smoothly, I’m glad for you and your patients. However, if that’s the case, this article may not be relevant to you.

The Locator Implant Attachment System is well-known and recognized for many applications in treating edentulous patients. The treatment planning concepts that capture my interest focus on the boundaries or limits of application in this scenario. Specifically, I work with individual locator abutments and four dental implants to support a mandibular overdenture.

Why Does the Locator Abutment/Attachment System Work so Well?

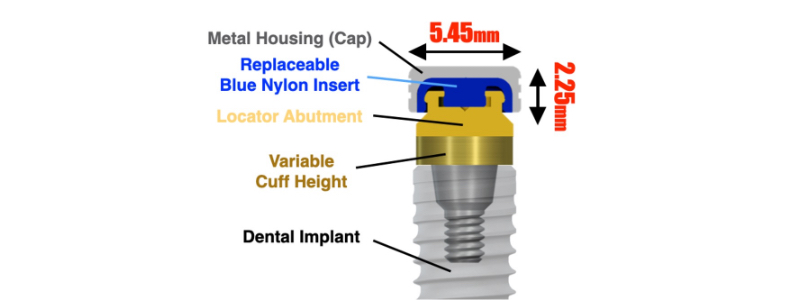

The gold locator abutment is connected to the dental implant like an abutment screw using a torque wrench. The metal housing (cap) and the replaceable nylon insert are incorporated into the removable overdenture prosthesis.

The low profile helps to accommodate restorative space limitations. Specifically, the requirements include 2.0 mm of denture-based acrylic surrounding the metal housing so that the materials work as intended.

The locator abutment/attachment system’s advertised features include several retention levels, ease of use, and the ability to manage angled dental implants relative to one another. It all sounds great — until it doesn’t work.

At What Point Will This System Not Work, Where Is the Line With Locators?

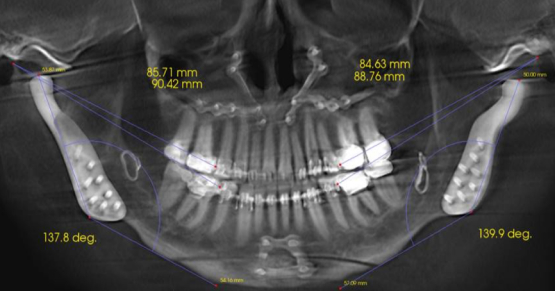

This patient (Fig. 2) had her remaining lower teeth removed, and following the insertion of the lower prosthesis, she has made several trips to have the Locator attachments changed. The patient describes going through this process every two weeks or so and is curious if something else can be done to improve retention and stability while decreasing the time invested in maintenance.

What do you see?

- Missing lateral incisors … potential arch width discrepancy.

- Upper natural dentition opposing and perhaps overpowering the lower overdenture.

- Locator Abutments appear divergent … extended range attachments have less retention as they do not engage the middle of the gold locator abutment.

- The mandibular arch could be described as advanced alveolar ridge resorption with limited vertical height and limited horizontal width of the hard and soft tissue supporting structure.

- One of the implants (#23 or 3-2) contains a cover screw rather than a locator abutment.

- In this scenario, a two-implant mandibular overdenture is likely not the right choice for the opposing maxillary dentition, which is on track with four dental implants.

- The arrangement or position of the dental implants is less than ideal — I prefer more space between the implants. The goal would be to have a more posterior position for the terminal implants.

When considering the position of the dental implants, would a connecting bar work for this patient? Any treatment scenario will likely require an accommodation for angle correction of the dental implant fixtures. What about an implant-supported lower hybrid (all-on-X)?

What else is possible? Think about this patient. They have invested in their dental health, and it seems to be a stretch financially. The result is a high-maintenance locator over denture, where she is required to come to the dental office every two weeks to change the attachments.

If the patient presented with an upper complete removable denture, it is possible to use the anterior implants as an “indirect retainer” to limit the rocking of the lower overdenture prosthesis. The two terminal or most posterior implants are positioned to create a fulcrum where a lower overdenture would rock anteriorly, working with only soft tissue support in the anterior segment.

This patient has a full natural dentition in the maxillary arch — the recommendation would not be to remove the upper teeth to make this work. Removing and replacing implants or simply adding additional implants if the restorative space is adequate with the existing implants comes to mind. The goal would be to create the appropriate foundational support expected of four or more dental implants for a removable prosthesis.

What About a Phased Approach to Treatment?

The question is … is there a way to help this patient out of a frustrating outcome that provides the opportunity to make treatment decisions resulting in a long-term, low-maintenance result?

The Conus abutment/attachment system is based on a friction-fit telescopic (conometric) design that provides a non-resilient connection with removable prostheses supported by a minimum of four dental implants. The limit for the available angle correction with the Conus system is 30 degrees.

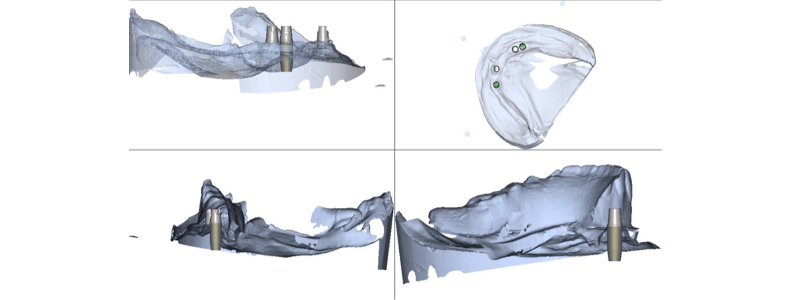

In this scenario, customized Conus abutments will be used to correct the relative angulation of the existing mandibular dental implants. The goal is to create a single insertion path for the removable overdenture prosthesis.

Working through this process requires a modified workflow with the ability to cross over between the traditional analog techniques and the virtual realm enhanced by computer aided design techniques.

Working virtually requires identifying the desired tooth position relative to the position of the dental implants — information that is identified and recorded clinically. The information is sent to the dental laboratory for the digital design and construction of the custom “angle-correcting” Conus abutments.

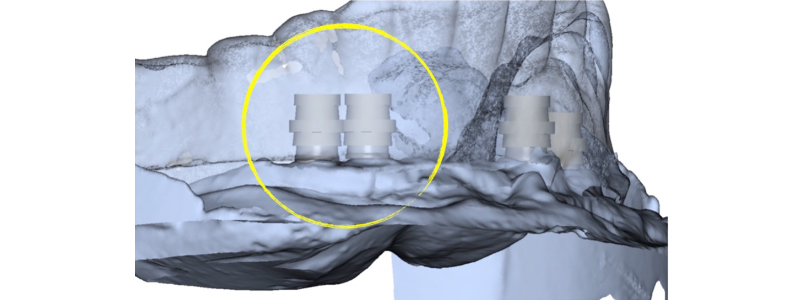

The computer design software creates an opportunity for improved communication using screenshots where the technician highlights an area of concern prior to moving forward with milling the customized “angle corrected” Conus abutments.

The question is, can we work with this or not? We can measure virtually and evaluate from multiple angles to help decide prior to proceeding with the treatment plan.

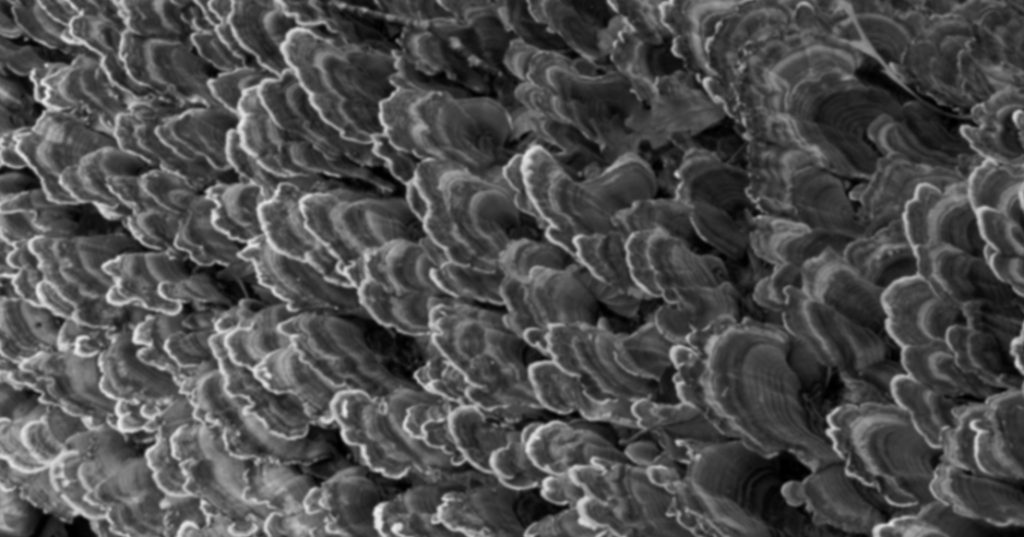

The prefabricated Syncone caps are designed to work with the five-degree taper built into the customized Conus abutment. As shown in the photo, the Syncone caps are available with aggressive retentive features.

The Syncone caps are also available with a smooth surface designed for cementation into a metal intaglio framework. When picking up the Syncone caps into an acrylic denture base using auto-polymerizing resin, it is recommended to work with Syncone caps with retention.

In this scenario, the Syncone caps have been modified to create space for the acrylic where the dental implants were placed in proximity. This was identified and discussed in the planning stages, as the virtual design software identified the concern, allowing the opportunity to communicate with the technician.

White auto-polymerizing acrylic is used to pick up the prefabricated Syncone caps using a “chairside” technique. The color difference improves the visibility for cleaning up excess resin that may form a thin veneer of material on the intaglio of the removable overdenture prosthesis.

The space requirements as advertised include 5.5 mm vertical height for the Conus abutment and Syncone cap, and an additional 5.0 mm to account for the acrylic and denture tooth. Working with space measurements beginning at the restorative platform of the dental implant on one end and the incisal edge or cusp tip of the denture tooth, 14.0 mm, provides a practical recommendation for space requirements when working with an acrylic-based removable overdenture. 15.0 mm would be recommended when incorporating a metal intaglio framework.

The modification to the existing overdenture design was changing the abutments from locator to Conus. The point was to determine if altering one variable could make a difference in the outcome in this scenario. This patient has gone from having to have the nylon locator attachments replaced on a two-week interval to a point where it is a challenge to have the patient come into the office for an evaluation.

It’s understandable that a break from the dental office was needed. However, we now have the opportunity to plan for continued care with the confidence generated from a proof-of-concept prototype.

SPEAR campus

Hands-On Learning in Spear Workshops

With enhanced safety and sterilization measures in place, the Spear Campus is now reopened for hands-on clinical CE workshops. As you consider a trip to Scottsdale, please visit our campus page for more details, including information on instructors, CE curricula and dates that will work for your schedule.

By: Doug Benting

Date: April 5, 2021

Featured Digest articles

Insights and advice from Spear Faculty and industry experts