3D Printers in the Age of Digital Dentistry

Advances in digital dentistry have led to greater consistency, predictability, cost-effectiveness, and enhanced workflows compared to the analog model. Although analog dentistry remains necessary in specific clinical situations (e.g., full edentulous arch impressions, implants, verification impressions, and facebow transfers), as technology continues to improve, many believe that practitioners will be able to incorporate these aspects into digital restorative treatments. Therefore, dental providers and laboratories need to understand recent advances in digital dentistry and how they will impact the restorations used and fabricated each day.

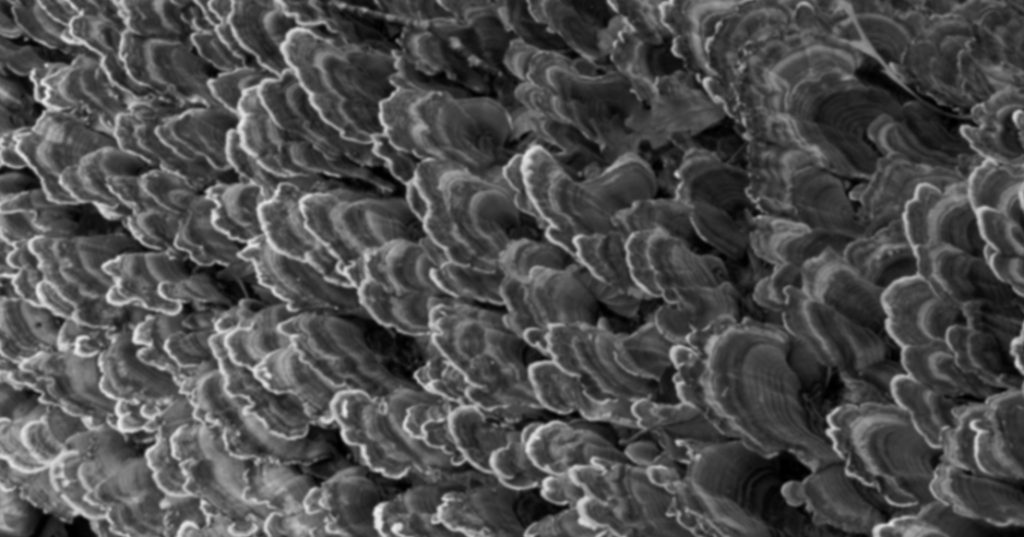

Carbon3D is a company that reports having developed a method to enhance the physical properties of restorative models and dies. Their technology, called digital light synthesis (DLS), is combined with their patented dental resin, DPR10, to fabricate digitally printed dental models. DLS, enabled by Carbon’s proprietary technology, is a breakthrough process that utilizes digital light projection, oxygen-permeable optics, and programmable liquid resins to digitally print models with excellent mechanical properties, resolution, and surface finish.

The company states that physical characteristics such as model and die hardness, accuracy and repeatability are improved, as well as printing speeds and fabrication for restorative dentistry and orthodontic treatments. The company has designed and sells two types of digital printers (the M1 and the M2) that combines DLS and DPR10 for use in laboratory and dental practice model fabrication.

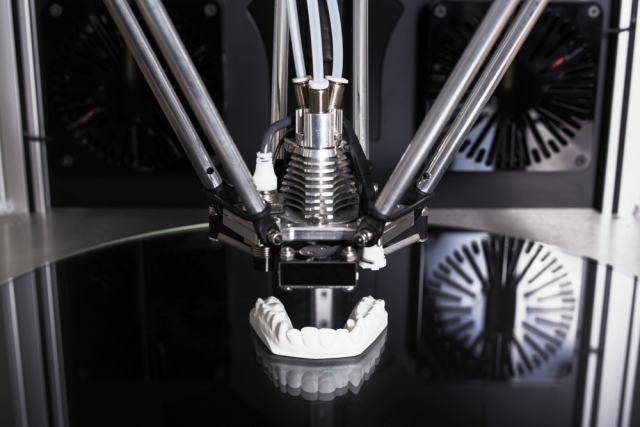

There are multiple advantages to Carbon’s 3D printers. One of the most significant advantages is the decrease in cycle times. Current 3D printers require 5 to 8 hours to fabricate models and an additional hour for post-print processing. Carbon 3D printers can print and process 10 times faster, resulting in improved production efficiency and lower costs within dental and orthodontic laboratories. These savings could be passed on to dental offices, since lab time to fabricate restorations would be decreased.

Additional advantages of Carbon’s 3D printers are their advanced software, ease of use, and customer support. The company is committed to ensuring both the printer and the lab function optimally by constantly upgrading software to ensure clinical success and accuracy. Since many 3D printers have maintenance issues, this support is vital to maintain laboratory productivity by reducing downtime for repairs and maintenance.

Carbon’s software can also integrate with computer-aided design (CAD) systems to create repeatable and scalable print solutions combining various digital methods of information gathering. However, due to the cost of the printers, a dental office would have to have significant case volume to justify return on investment.

Carbon3D’s advanced software is the innovation that interests me the most as a restorative dentist. Accurate models are paramount to successful restorations. Carbon reports improve accuracy of printed models by creating improved resolution and an excellent surface finish with fewer striations. While some dentists are completely digital with their restorations and are model-free, various clinical situations still require model fabrication.

Importance of Accuracy in Printed Dental Models

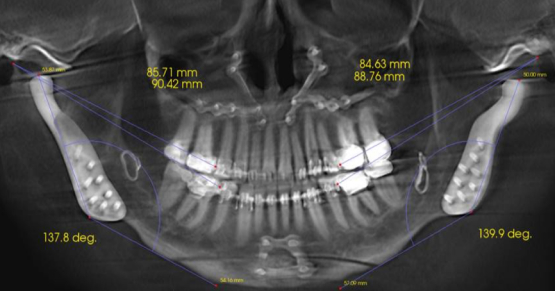

It is paramount for predictable and accurate restorative outcomes to have a printed model that is equally accurate. I have personally observed a great variety in the quality of printed models; this variability in quality affects how restorations fit clinically. Inaccuracies in printed models result in a poor adaptation of the restoration to the model and dies. This results in poor restoration fit, marginal integrity, and ultimately, restoration failure.

The quality of printed models directly affects the long-term prognosis of restorations, and while the dental community may believe that if we take a digital impression, our restorations should be flawless, we know this is not always the case. We as practitioners must understand the options we have and how it can affect our overhead and clinical results.

It is important for our labs to be aware of the physical properties of printed models and seek to use the most accurate and predictable materials. Carbon claims to have a superior fabricating process and resin material. Time will tell if this is true. As restorative dentists, it is important that we all stay abreast of the technological advances, changes and potential pitfalls in digital dentistry.

VIRTUAL SEMINARS

The Campus CE Experience

– Online, Anywhere

Spear Virtual Seminars give you versatility to refine your clinical skills following the same lessons that you would at the Spear Campus in Scottsdale — but from anywhere, as a safe online alternative to large-attendance campus events. Ask an advisor how your practice can take advantage of this new CE option.

By: Andrew Cohen

Date: January 21, 2018

Featured Digest articles

Insights and advice from Spear Faculty and industry experts