Replacing Triad Provisional Material

Durasplint LC is easy to handle and solves the problem of losing Triad provisional in our anterior bite planes.

Triad provisional material (Dentsply) has been an extremely useful and versatile material in many dental practices and in our campus workshops. The light-cured, resin-based material was known for its color stability, polishability, and relative ease of manipulation. Unfortunately, earlier this year, production of this material was cancelled and it is no longer available from the manufacturer.

To be clear, many different Triad materials, including the clear tray material, are still available. While that’s good news, clinicians still need to replace the provisional material.

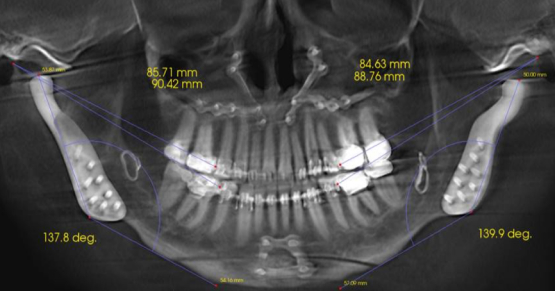

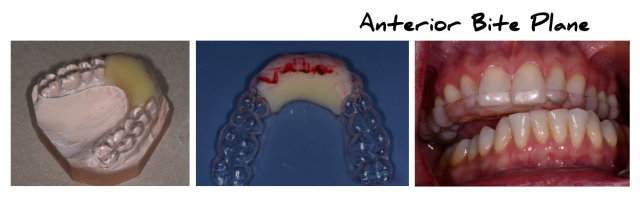

One area where this material has been extremely useful is in the construction of anterior bite planes. The fabrication process utilizes a relatively rigid thermoplastic base (Splint Biocryl 1.5 mm, Great Lakes Ortho) with a flat anterior portion that is customized for the patient’s occlusion and fabricated from Triad provisional material. This fabrication process is efficient and relatively easy to complete in the office.

Possible solutions for Triad provisional material replacement

One obvious solution to this problem is to delegate fabrication to the dental laboratory and let the technician work around the material problem. The primary disadvantage to this option is the amount of time required to get the case to and from the lab, essentially canceling one of the key benefits of this appliance’s design.

Another possible solution, for those with in-office milling, is to digitally design and fabricate the appliance. Dr. Kevin Kwiecien discusses the pros and cons of this method using CEREC in this article about going digital with the anterior bite plane.

A third possibility is to return to the material previously used for these appliances. In this case, it was powder and liquid PMMA. PMMA is available in a variety of colors, including tooth-colored and clear. PMMA wears well, is easily adjusted and polished, and is inexpensive. The primary disadvantage of PMMA is its handling characteristics. Because the material is self-cured, working time is limited. Still, acrylic can be a great option.

What material are we using?

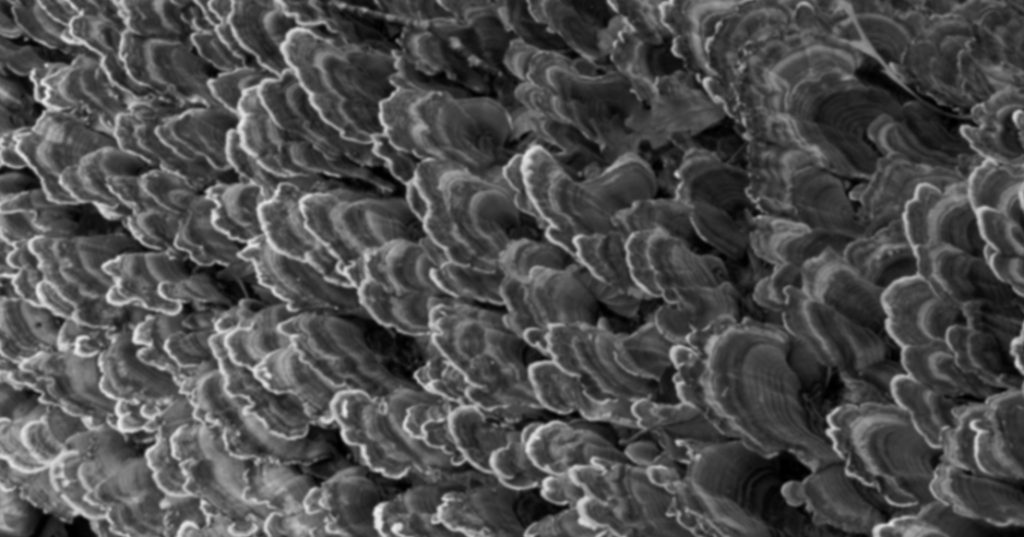

For both our campus workshops and our faculty practice, rather than go back to acrylic/PMMA, Great Lakes Ortho has helped source an alternative material from Scheu. The material, Durasplint LC, is a clear, light-cured putty. Its handling characteristics are similar to those of the Triad provisional material, and it may be bonded to Biocryl exactly the same way.

Durasplint LC is easy to handle and solves the problem of losing Triad provisional in our anterior bite planes. Because we’ve only just begun using this material, it’s probably too early to speculate on its durability, yet what we’ve seen up to this point is definitely positive.

We’d love to know what materials you use. Be sure to let us know in Spear Talk. You can also learn more about occlusion and appliances here.

SPEAR NAVIGATOR

Transform how your practice runs by engaging the team through

coaching and training

A guided path to excellence through structured coaching and self-guided resources that will align your team, streamline processes and drive growth. Transform your practice by implementing Spear’s proven playbooks for developing and retaining a high-performing dental team.

By: Darin Dichter

Date: December 21, 2016

Featured Digest articles

Insights and advice from Spear Faculty and industry experts